Advanced downstream bioprocessing

- Duration: 4 days

- Price: £2,950 + VAT

- Dates: TBC

This 4-day course delves into the complexities of downstream bioprocessing performed in modern biomanufacturing facilities with an enhanced focus on advanced therapies, biotherapeutics and vaccines.

Delegates will gain a deep understanding of the unit operations involved in downstream processing such as harvest strategies, chromatography, viral clearance, ultrafiltration/diafiltration and fill-finish as well as design of experiment concepts.

Accompanying talks delivered by our expert industry partners will outline current advances in recovery and purification technologies to ensure that delegates receive the most up-to-date knowledge in bioprocessing.

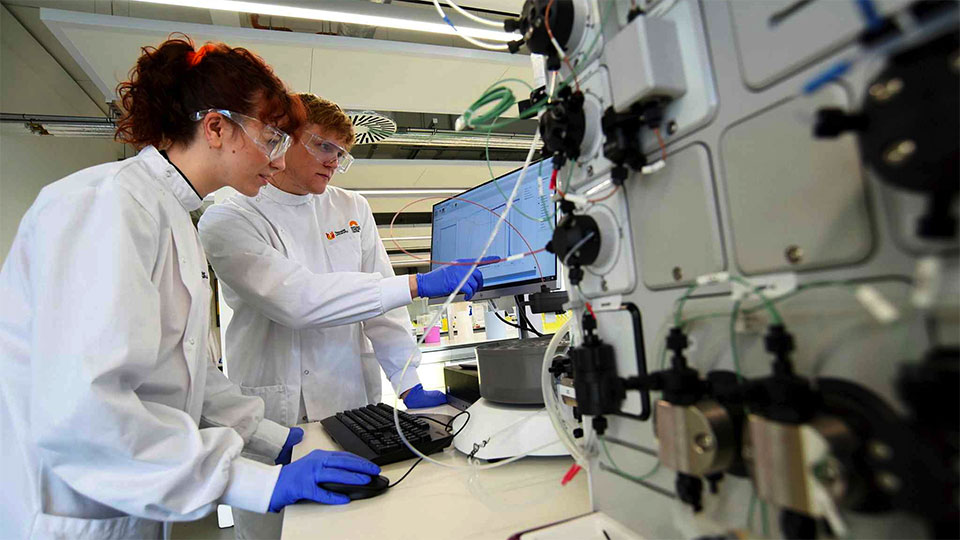

Training will be conducted in our Centre of Excellence facility housing cutting-edge laboratory instruments and benchtop-scale processing equipment, allowing delegates to gain vital hands-on practical exposure to industry-standard biomanufacturing processes and procedures.

Topics covered:

- Control systems for downstream processing

- Harvesting strategies for different cell lines

- Viral safety & clearance

- Downstream filtration methods

- Protein purification and chromatography

- Process analytical technologies for downstream processing

- Continuous downstream manufacturing

Training partners

Who should attend:

- Scientists, technical staff, engineers, and managers with at least 3 years’ experience within the biotechnology industry wishing to increase their knowledge of downstream operations in a modern bioprocessing plant, through lectures and hands-on training.

Course dates

TBC

For more information, general enquiries and details of the full agenda, please email CPDNHC@tees.ac.uk

Register your interest

View full list of courses