Course overview

The programme of lectures and project work, encompasses a wide range of petroleum and geoenergy fundamentals, which play an important part in the modern petroleum, CCUS and hydrogen industry. Project work provides an opportunity for ideas and methods, assimilated through lectures and tutorials, to be applied to real field evaluation and development design problems. The course is applied in nature and has been designed so that on completion, you are technically well prepared for a career in industry.

Course details

Course structure

Core modules

You investigate an area of engineering and work independently to a level recognised to be at the forefront of the discipline. The topic can be in the form of a research project or a design project. Key skills in research and in knowledge application and creation will be developed through keynote lectures and self-managed independent study. You are required to demonstrate the capacity for a comprehensive and objective analysis, and for developing innovative and constructive proposals for the solution to the project topic.

Hydrocarbon Exploration and Production Engineering

This module will provide a detailed understanding of hydrocarbon exploration and production. The module will cover different methods of hydrocarbon exploration, drilling engineering, the process of well completion, and work-over. Moreover, it covers the oil and gas production systems including wells, pipelines, separators and chokes. The inflow performance relationships (IPR) for oil and gas wells, as well as well performance analysis will be included in this module. The module will also provide the understanding for surface production facilities and operations used in crude oil treatment and natural gas re-conditioning such as sweetening and dehydration.

This module will be delivered through a combination of lectures and tutorial sessions.

The module provides you with an understanding of crude oil fractions and components enabling you to study the phase behaviour of reservoir fluids as a function of temperature and pressure. We use different equations of state to analyse the pressure-volume-temperature correlations. You explore how constructing compositional fluid models, using an industry-standard reservoir simulator, enables you to investigate reservoir fluid properties and behaviour. You also discuss oil field corrosion and scaling mechanisms as well as monitoring and inhibition methods. This module is delivered through lectures, tutorials, and IT laboratory sessions. You are assessed by an in-course assessment (30%) and exam (70%).

Petroleum Economics and Simulation

This module provides you with a detailed understanding of petroleum economics as well as concepts related to asset and project assessment and valuation. You investigate the economics of the oil industry and the cost stabilities of large oilfields and their economies of scale. You look into industry-standard reservoir simulators, their theoretical background, and their uses and limitations. You develop an understanding of reservoir management by integrating different operations, sub-processes and upstream activities. This module is delivered through a series of lectures supported by tutorials and IT laboratories. You are assessed by an in-course assessment (30%) and exam (70%).

Petroleum Reservoir Engineering

This module covers the key concepts of reservoir engineering including reservoir properties, single and multiple-phase fluid flow through porous media. You are introduced to various reservoir rock types including carbonate and sandstone rocks, and the geological aspects of hydrocarbon reservoirs. You discuss formation evaluations based on well-testing and well-logging interpretations. This module is delivered through lectures supported by tutorials. You are assessed by in-course assessments (30%) and exam (70%).

Quality, Health, Safety and Environment

The module provides an understanding of the aims, responsibilities and means to achieve effective Quality, Health, Safety and Environment (QHSE) management systems in Oil and Gas related organisations.

This module presents a number of core and specialist areas appropriate for effective management of QHSE in a successful oil and gas related organisation. Critical components of Safety Management (including a QHSE plan, process safety, hazard identification, safety auditing and managing risk) form a comprehensive part of the core study underpinning the total Safety Management System (SMS). Where appropriate, actual industry examples are used as case studies to enhance the students’ learning and to demonstrate the mechanisms used, and impact of, legal and administrative compliance. Further, the relevance of occupational health and safety and also sustainability in safety are discussed in terms of best industry practice.

The importance of implementing a Total Quality Management (TQM) system and the impact on the industry/organisation will be emphasised to students. Environmental drives and current issues, including an Environmental Impact Assessment will complete this part of the programme content.

Sustainability in Chemical Engineering

This module covers environmental assessments such as life cycle assessment, environmental impact assessment and environmental management system on environmental impacts from industrial and human activities. You also gain an understanding of sustainable engineering strategies such as clean technology and renewable energy to address current environmental issues.

Modules offered may vary.

How you learn

The course is delivered using a series of lectures, tutorials and laboratory sessions.

Our MSc Petroleum Engineering is supported by excellent laboratory and engineering machine workshop facilities including fluid flow measurement, computer modelling laboratories, other laboratories and workshops, an excellent library and computing facilities. We have invested around £150,000 in laboratory equipment particularly within core analysis and enhanced oil recovery, carbon capture and storage and underground hydrogen storage.

Schlumberger, Oilfield UK plc has donated a software package that helps advance your research. For upstream processes, Teesside University has access to educational software packages like Petrel, Eclipse, CMG, PIPESIM and Ecrin to simulate the behaviour of oil reservoirs, calculating oil in situ, and oil and gas production optimisation. As for downstream processes, you can use HYSYS to test different scenarios to optimise plant designs.

PE Limited has donated to Teesside University a network system and 10 educational licences for the IPM suite (Integrated Production Modelling software) which includes Prosper, Gap, Mbal, Pvtp, Reveal and Resolve. This £2.66m system and software is used by our students to design complete field models including the reservoir tanks, all the wells and the surface gathering system.

Laboratory facilities

Hydrogen and CO2 underground storage laboratory

The energy lab offers you safe high-pressure and high-temperature vessels to test different underground reservoirs for hydrogen seasonal storage. Different types of reservoirs can be tested for their suitability for permanent greenhouse gas storage. The energy lab can be also used to investigate different types of carbon capture, utilisation and storage and renewable resources such as biochar, biofuel, natural clay minerals, hydrogen, ammonia as well as direct carbon capture.

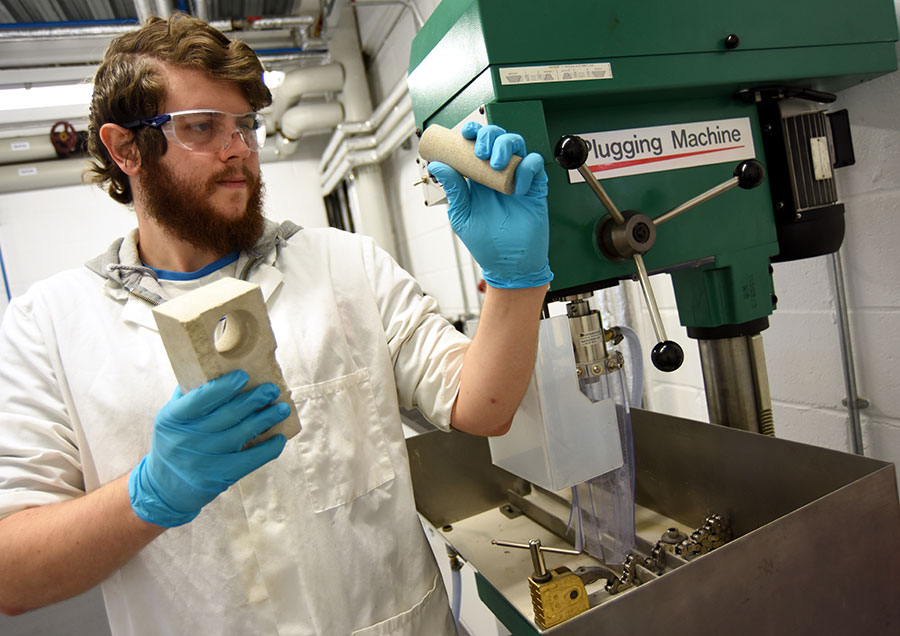

Enhanced oil recovery and core analysis laboratory

The core flooding lab at Teesside can be used to study the flow through porous media and enhanced oil recovery techniques. The lab is equipped with core preparation machines such as core plugging and core trimming, and core saturators. In addition, all routine core date can be measured in this lab. At a higher level, the lab is also equipped to perform some special core analysis measurements such as fluid relative permeabilities as well as rock surface wetting quantification.

Petrophysics laboratory

The petrophysics lab allows you to study the properties of rocks, particularly the measurement of porosity and evaluation of permeability. The lab is equipped with sieve analysis equipment to investigate grain sorting and its effect on permeability and porosity of the rocks. Atomic and molecular structure of a mineral can also be studied with x-ray diffraction (XRD) in our petrophysics lab.

Surface characterisation laboratory

The rock surface characterisation lab is equipped with a zeta analyser to measure the rock surface electric charge. You study the rock surface wetting state, adsorption and desorption potential using digitised contact angle apparatus and thermos-gravimetric apparatus respectively. This lab also offers you to study the rock surface at micro level using facilities such as Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM) images, XRD and

energy-dispersive x-ray spectroscopy (EDX).

Drilling laboratory

The drilling lab is equipped with drilling mud measurement equipment including mud density, mud rheology and mud filtration systems, enabling you to study mud cake and formation damage. The lab highlights the importance of oilfield drilling fluids.

How you are assessed

Assessment varies from module to module. The assessment methodology could include in-course assignments, design exercises, technical reports, presentations or formal examinations. For your MSc project you prepare a dissertation.

Entry requirements

Applicants are normally expected to have at least a 2.2 UK honours degree or equivalent qualification. A wide range of degree subjects are acceptable, including petroleum engineering, mechanical engineering, chemical engineering, chemistry, chemical process engineering, oil and gas engineering.

Students with a degree awarded outside the UK must also meet the University's minimum English language requirements.

International applicants who need a student visa to study in the UK should check our web pages on UKVI-compliant English language requirements. The University also provides pre-sessional English language courses if you do not meet the minimum English language requirement.

For general information please see our overview of entry requirements

International applicants can find out what qualifications they need by visiting Your Country

Employability

Career opportunities

These courses provide specialist education tailored to the requirements of both the upstream and downstream petroleum industry. The relevance of this education combined with careful selection of candidates has encouraged oil and gas companies to target our graduates for recruitment over the years.

The petroleum industry is subject to dramatic changes of fortune over time, with the oil price capable of very rapid rates of change in either direction. Petroleum, however, remains the dominant source of energy, with current world production of oil and gas at record rates. In this environment, companies face increasing technological and commercial challenges to keep their wells flowing and are increasingly dependent on input from petroleum engineers and geoscientists.

It is widely recognised that a steady influx of fresh people and ideas is vital for the longer-term success and stability of an organisation, and it is therefore expected that recruitment will continue, especially for those with motivation and the appropriate qualifications.

Information for international applicants

Qualifications

International applicants - find out what qualifications you need by selecting your country below.

Select your country:

Useful information

Visit our international pages for useful information for non-UK students and applicants.